The ZAG project is an exploration of the potential of fused deposition 3D printing (FDM). This research aims to highlight the specific qualities of this manufacturing technique.

I started this work in 2018, as part of the specialized Master’s degree “Creation and Contemporary Technology” at ENSCI – Les Ateliers.

Context

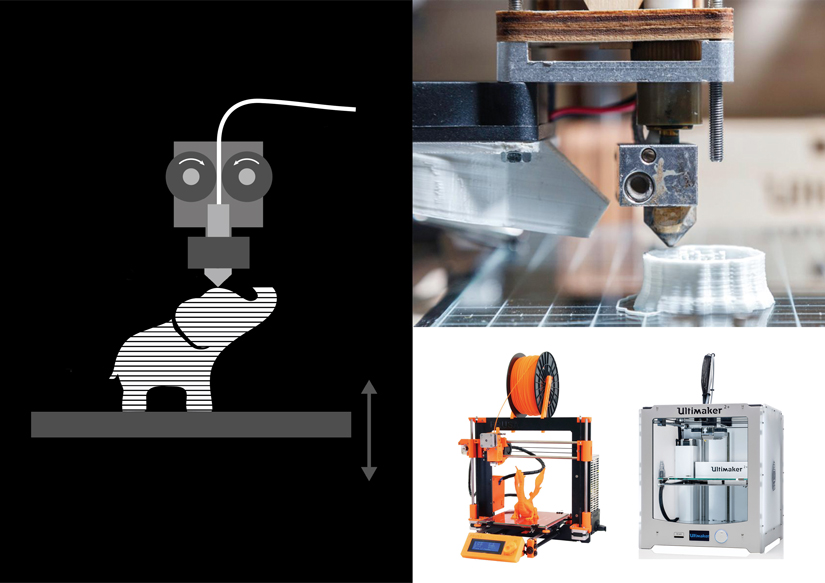

The RepRap project, founded in 2006, democratizes 3D printing using the principle of Fused Deposition Modeling (FDM). Previously, 3D printing, and more generally the digital techniques of additive manufacturing, were reserved for industrial prototyping and research, due to the high cost of machines.

This “democratization”, made possible by desktop FDM 3D printing, has been at the origin of “utopias” linked to the idea of personal digital manufacturing, and to the crossroads of the “DIY” and “Makers” movements, as well as the emergence of fablabs (cf. Jeremy Rifkin, Chris Anderson…). But today, almost ten years later, this technology is often associated with the manufacture of uninteresting “gadgets”. Paradoxically, it seems that FDM 3D printing is perceived as an increasingly unconvincing technology, even though it is increasingly present around us.

Right: Examples of downloadable objects on thingiverse.com website

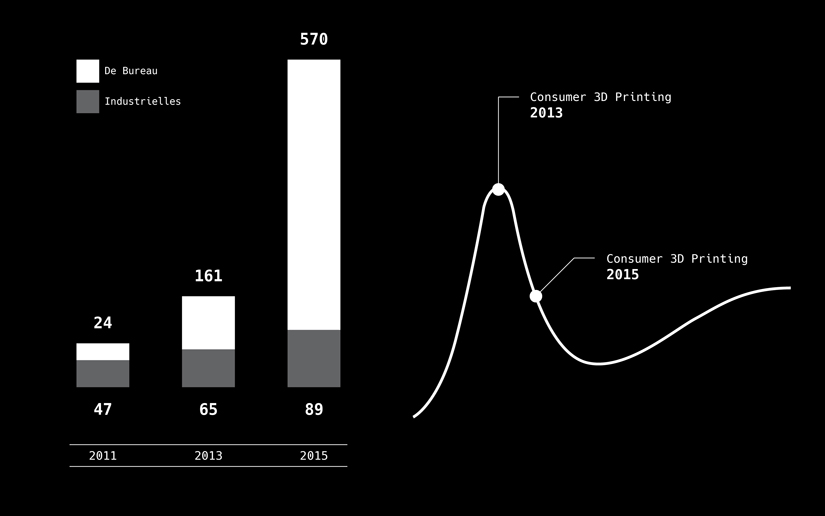

Right: Hype curve of emerging technologies (source: Gartner Reports 2013 / 2015)

The starting point of the ZAG project is therefore that FDM 3D printing is possibly underestimated, due to a lack of identification of its specific qualities.

Inspirations

The spread of “personal” 3D printing, probably through a mediatization effect, has also caused unprecedented dynamism in the global sector of 3d printing. The evolution of 3D metal printing (DMLM), the emergence of 3D printing in concrete, ceramics, and bio-impression, have enabled the development of innovative solutions in various fields (health, energy, architecture, ecology, engineering…).

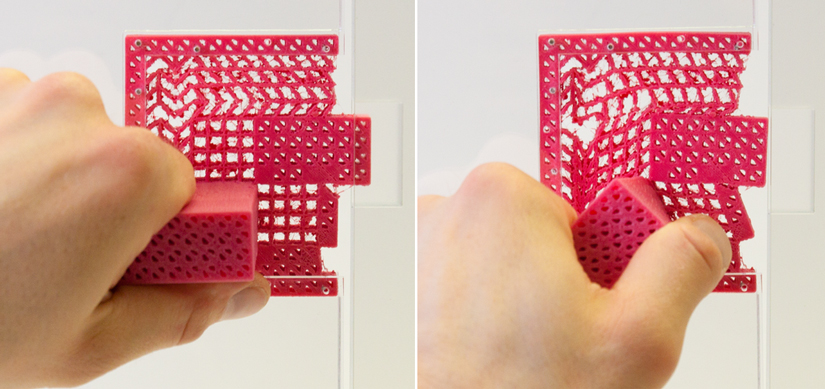

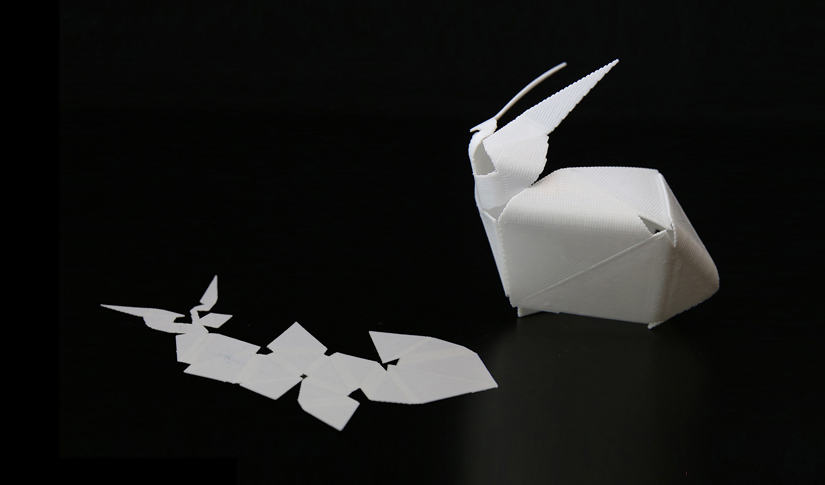

The structural properties exploited by some of these works have been sources of inspiration in this project, as have some recent research areas: “metamaterial-mechanisms” (integrating mechanical behaviours into the structure of the material itself), 4D printing (the object finishes manufacturing itself autonomously, its material having been “programmed” for this purpose), “tangible” interfaces…

Metamaterial Mechanisms – Hasso Plattner Institute HCI Lab, 2016

Thermorph – Morphing Matter Lab, 2018

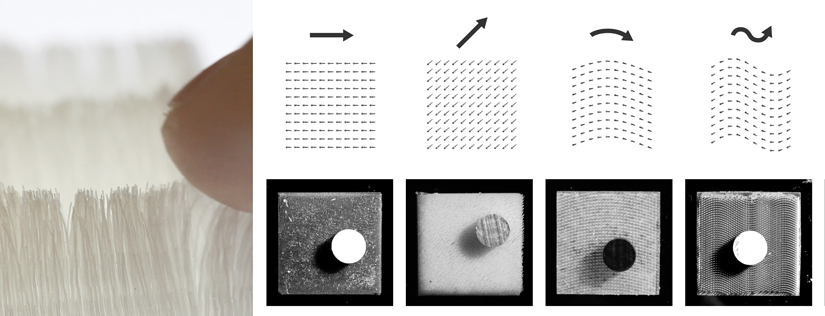

Cilllia – Tangible Media Group, MIT, 2016

Cool Brick – Emerging Objects, 2015

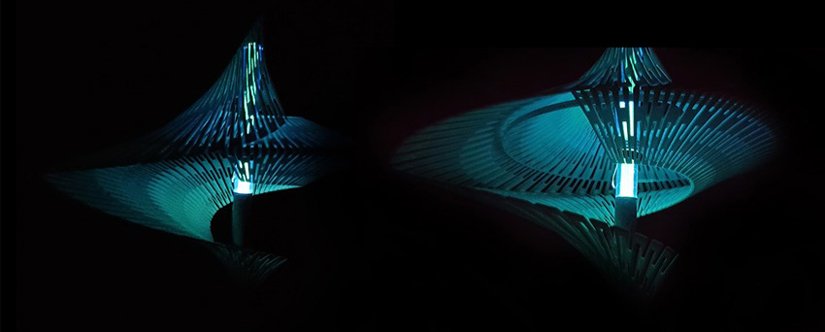

Seismic LED – Margot Krasojevic, 2017